Steam-Tunnels

for Shrink Sleeves

Technical Details:

- waterproof

- consistent steam distribution due to low-pressure steam drum

- height-adjustable steam steel pipes

- adjustable steam output

- optionally combinable with conveyor belt and sleeve labeling machine

How does a steam tunnel work?

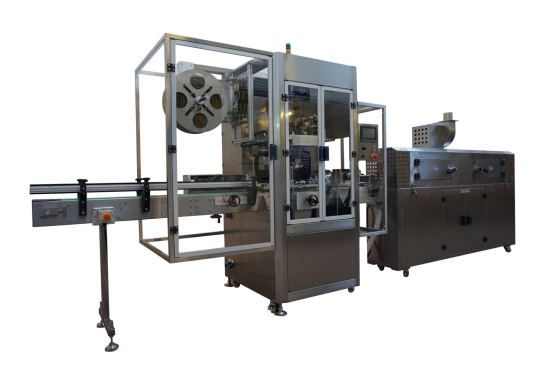

Steam tunnels are particularly suitable for shrinking heat-shrinkable film sleeves onto products of all kinds (jars, PET bottles, glass bottles, cans and many more). Our steam tunnels are easy to use and the cost-effective alternative to conventional shrink tunnels based on electric heaters.

A steam tunnel rarely stands alone, but is usually combined with a sleeve packaging machine. The length of our steam tunnels can be customized for specific products according to customer requirements and depends on the product to which the shrink sleeve is to be applied. Generally speaking, steam tunnels can be divided into 2,3,4 and 5 stage steam tunnels. Each chamber has a different steam pressure to achieve the best shrink process. This steam pressure can be adjusted very easily by pressing a button.

The advantages of our steam tunnels:

Our SST-1500 and SST-2500 series sleeve steam tunnels are extremely easy to operate and maintain, waterproof and easy to clean. They can be used for efficient shrinking of full-body sleeves on almost any type of container with almost any sleeve material. The low-pressure steam drum distributes steam evenly throughout the tunnel through the integral tubular steel construction. Steam steel tubes are located in each chamber of the tunnel and are adjustable in both height and steam output. The housing of the tunnel as well as the water collection plate for collecting condensed water are made of 304 stainless steel.

We are particularly distinguished by our flexibility in shrink tunnel machines: Both the size of the tunnels and the conveyor belts running in them can be adapted to your individual requirements. We are also happy to take over the maintenance of the equipment for you.

Steam Tunnel with Sleeve-Labeling-Machine: Bottle Labeling

Steam Tunnel with Sleeve-Labeling-Machine: Bottle Labeling

Different Models:

Optional Accessories:

Steam Generator:

Our electric steam generators STG-24 and STG-36 consist of a high-pressure chamber filled with water and heated by electric underwater heaters. The machine additionally features automatic controls to maintain the set operating temperature and water level.

Safety features: automatic low water shutoff, dual pressure controls. safety valve and visible water level gauge.